Flakes System

Components

- Concrete or substrate: This is the base layer upon which the entire flooring system is built. Proper surface preparation is essential for a successful flake epoxy flooring installation. The concrete surface must be clean, dry, and free of dirt, dust, grease, or existing coatings.

- Pigmented basecoat: This is a colored layer of epoxy that’s applied over the concrete substrate. The basecoat provides a consistent background color for the entire flooring system.

- Flakes: These are small, decorative chips or flakes made from vinyl or acrylic, that provide extra resistance to your flooring system, and are broadcast onto the wet pigmented basecoat. They come in a variety of colors and sizes and are used to create a speckled, textured effect on the surface.

- Clear topcoat: This is a final layer of clear polyaspartic that’s applied over the flakes and pigmented basecoat. The topcoat provides a glossy, protective finish that seals and protects the surface from stains, abrasions, and UV rays.

Advantages

- It offers a broad range of options in terms of finishes and blends, allowing users to customize their coating to fit their specific needs and preferences.

- It can be used on both floors and walls, making it versatile and useful for a variety of applications.

- Minimal maintenance is required for this type of coating, making it a cost-effective option for long-term use.

- The contoured finish provides excellent traction, which is especially important for safety on floors or other surfaces that require a non-slip finish.

- This type of coating offers excellent resistance to various chemicals, including gasoline, oil, and de-icing salts, making it an ideal choice for industrial and commercial environments where spills and leaks are a common occurrence.

Applications

- Garages

- Recreational Facilities

- Basements

- Patios

- Grocery

- Schools

- Balcony

Our Flake System Built With 4 Layers For Lasting Strength, Is A Non-Slip Choice For Your Places

At Maui Epoxy Solutions, we take pride in offering a wide range of flooring solutions to elevate your space. Among our most popular options are flake system epoxy floors, also known as flake flooring systems or simply flake systems. These versatile and durable floors combine the strength of epoxy with the aesthetic appeal of decorative flakes, creating a unique and functional surface for homes and businesses alike.

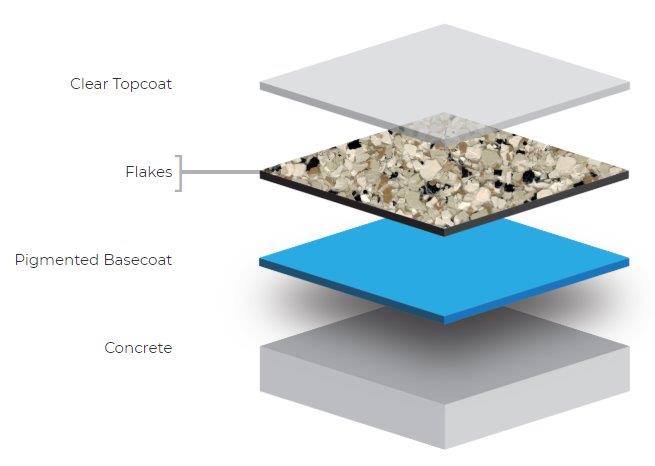

The Components of a Flake System & A look On Its Multi-layers

A flake system floor is a multi-layered masterpiece. Let’s delve into the components that make it up:

- The 1st Layer – Concrete or substrate

This is the base layer upon which the entire flooring system is built. Proper surface preparation is essential for a successful flake epoxy flooring installation. The concrete surface must be clean, dry, and free of dirt, dust, grease, or existing coatings.

- The 2nd Layer – Pigmented basecoat

This is a colored layer of epoxy that’s applied over the concrete substrate. The basecoat provides a consistent background color for the entire flooring system.

- The 3rd Layer – Flakes

These are small, decorative chips or flakes made from vinyl or acrylic, that provide extra resistance to your flooring system, and are broadcast onto the wet pigmented basecoat. They come in a variety of colors and sizes and are used to create a speckled, textured effect on the surface.

- The 4th Layer – Clear topcoat

This is a final layer of clear polyaspartic that’s applied over the flakes and pigmented basecoat. The topcoat provides a glossy, protective finish that seals and protects the surface from stains, abrasions, and UV rays.

The Advantages of Flake Systems Are The Mix of Functionality and Look.

Flake system epoxy floors offer a compelling combination of aesthetics, functionality, and practicality. Here are some key advantages that make them a popular choice:

- Flake flooring systems offer a vast array of color flake options and finishes, allowing you to personalize your floor to match your unique style. Whether you prefer a subtle and classic look or a vibrant and eye-catching design, our experts can help you achieve your vision.

- Flake systems are not limited to floors! They can also be applied to walls, creating a cohesive and visually appealing look throughout your space. This versatility makes them ideal for a wide range of applications, both residential and commercial.

- Flake systems with epoxy coating are a dream come true for busy homeowners and business owners. Their smooth, seamless surface requires minimal maintenance to retain its beauty. Regular sweeping and occasional cleaning are all you need to keep your flake epoxy systems floor looking its best, saving you time and money on upkeep.

- The contoured finish of epoxy flakes systems provides excellent traction, making them ideal for high-traffic areas and spaces where slip resistance is crucial. This is especially beneficial for garages, basements, and commercial environments.

- Epoxy resin flakes system floors are built to withstand the test of time, even in demanding environments. They offer superior resistance to a variety of chemicals, including gasoline, oil, and de-icing salts. This makes them a perfect choice for industrial and commercial settings where spills and leaks are a frequent occurrence.

Applications for Flake Systems Make Them Suitable For a Wide Range Of Places.

The beauty and practicality of flake systems make them suitable for a wide range of applications. Here are some popular examples:

- Transform your garage from a cluttered space into a garage floor flakes, organized, and visually appealing area with a flake system floor. The durable and stain-resistant surface easily handles heavy machinery and oil spills, while the custom design options add a touch of personality.

- Create a vibrant and inviting atmosphere in your gym, game room, or playroom with a flake system. The seamless surface is easy to clean and maintain, perfect for high-traffic areas, while the decorative flakes can add a touch of fun to the space.

- Breathe new life into your unfinished basement with a flake floor. It transforms a potentially damp and dark space into a functional and inviting area, perfect for a home theater, entertainment room, or workshop.

- Extend your living space outdoors with a beautiful and durable flake floor system. The weather-resistant finish and slip-resistant texture make it ideal for outdoor areas, while the custom design options allow you to create a seamless transition from your interior space.

- Impress your customers with a clean, professional, and easy-to-maintain floor in your commercial space. The acrylicon flake system can handle heavy foot traffic and resist spills and stains, while the variety of colors and finishes allow you to create a visually appealing shopping experience.

- Flake system floors are a perfect solution for schools and educational facilities. They offer a durable surface that can withstand the wear and tear of high foot traffic and active environments. The seamless and easy-to-clean surface minimizes the spread of germs, while the variety of flake color options can create a stimulating and engaging learning environment.

Find Endless Design Possibilities With Our Expertise Decorative Epoxy

Flake systems are not just about functionality; they are also a powerful design tool. With our expertise in decorative epoxy, we can help you create a custom floor that reflects your unique style and complements the aesthetics of your space.

We offer Seamless Epoxy Flooring & our flake system offers a seamless finish that eliminates grout lines and creates a visually unified space. This not only enhances the aesthetic appeal but also makes cleaning and maintenance effortless.

Our Custom Epoxy Design delivers creativity to let go the days of boring, cookie-cutter floors. We can work with you to incorporate custom designs, logos, or patterns into your color flake floor system, making it a true centerpiece of your space.

So, Find The Best Flakes System Floor With Our Epoxy Flooring Services

At Maui Epoxy Solutions, we are passionate about exceeding your expectations. We offer a complete range of epoxy flooring and flake floor services, from expert consultation and design assistance to flawless installation and aftercare guidance.

What sets us apart? It begins with our unwavering dedication to using high-quality materials. From premium-grade epoxy coatings to garage floor flakes sourced from reputable brands, we ensure that every product we use is of the highest caliber, guaranteeing exceptional durability and long-lasting performance.

But it’s not just about the materials, it’s also about the expertise behind the installation. Our team consists of highly skilled and experienced professionals who approach each project with meticulous attention to detail and a passion for craftsmanship. Whether it’s residential epoxy solutions or industrial flooring, we deliver flawless installations that exceed expectations.

So, if youe want to transform your space with a beautiful, durable, and easy-to-maintain flake system of a down floor? Contact Maui Epoxy Solutions today! We offer free consultations and estimates to help you determine the perfect solution for your needs. Let us help you create a floor that not only enhances the functionality of your space but also reflects your unique style.