Quartz System

Components

- Concrete or substrate: As with any epoxy floor system, proper concrete preparation is crucial. The concrete, which is the underlying surface that the quartz system coating will be applied to, needs to be thoroughly cleaned, etched, or ground to create a clean and rough surface for optimal adhesion of the coating.

- Pigmented basecoat or primer with Quartz Aggregate: This is the first layer of epoxy coating that is applied to the prepared substrate. It acts as a bonding agent, promoting adhesion between the substrate and the subsequent layers. The primer also includes a broadcast of quartz aggregate, which helps to create a mechanical bond between the epoxy and the substrate.

- Build Coat with Quartz Aggregate: The build coat is the main layer of epoxy coating that contains quartz aggregate. The quartz aggregate provides the floor with durability, chemical resistance, and slip resistance. This layer is typically broadcasted with additional quartz aggregate to achieve the desired quartz density or appearance.

- Top Coat: The top coat is the final layer of the quartz system that is applied over the build coat with quartz aggregate. It serves as a protective layer that enhances the durability, chemical resistance, and UV resistance of the quartz system.

Advantages

- Known for its superior durability and impact resistance

- Enables a rapid return to service

- Suitable for both interior and exterior use.

- Anti-slip

- Different color options

Applications

- Parking lot

- Garage

- Ramps and other high torque areas

- Exterior walk-ways

- Pool area

- Commercial kitchens

- Restrooms

- Locker rooms

Gain The Lasting Appeal and Strength In Your Places With Our Quartz Flooring Systems

At Maui Epoxy Solutions, we understand the importance of creating floors that are not only aesthetically pleasing but also incredibly durable and functional. That’s why we offer high-end quartz floor finishes, a superior solution for both residential and commercial spaces.

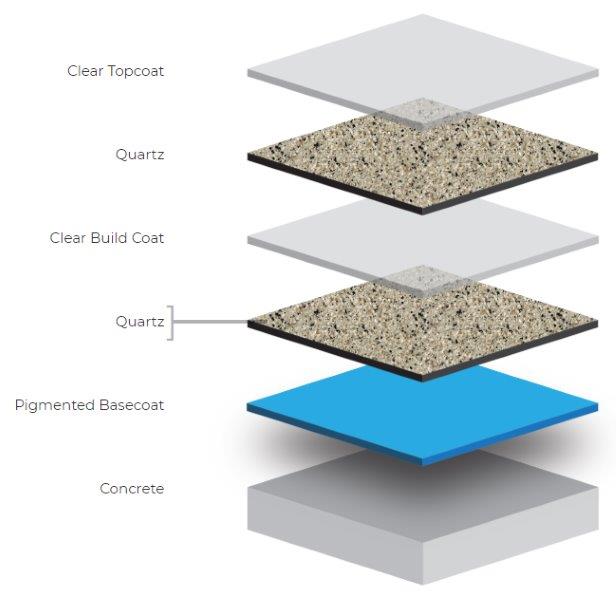

A Layered Approach To Quartz Flooring System Performance:

Our quartz flooring system is a masterpiece of engineering, meticulously crafted to deliver exceptional performance. Here’s a breakdown of its key components:

- The 1st Layer – Concrete or Substrate

A solid foundation is essential. As with any epoxy floor system, proper preparation of the concrete is crucial. This may involve cleaning, etching, or grinding to create a clean and rough surface for optimal adhesion of the quartz epoxy coating.

- The 2nd Layer – Pigmented Basecoat or Primer with Quartz Aggregate

This is the first layer, acting as a bridge between the substrate and the subsequent layers. The pigmented basecoat, also known as a primer, includes a broadcast of quartz aggregate. This aggregate helps to create a strong mechanical bond between the epoxy and the substrate, ensuring long-lasting durability.

- The 3rd Layer – Build Coat with Quartz Aggregate

The heart of the system lies in the build coat. This layer is the main body of epoxy coating and contains a significant amount of quartz aggregate. This aggregate is what gives quartz flooring its renowned durability, chemical resistance, and slip resistance. Additional quartz aggregate is typically broadcasted onto this layer to achieve the desired level of density and visual appeal.

- The 4th Layer – Top Coat

The final layer acts as a protective shield. The top coat is applied over the build coat with quartz aggregate, enhancing the overall durability, chemical resistance, and UV resistance of the entire quartz flooring system.

Quartz Epoxy Flooring Offers Beyond Beauty Practical Advantages

Quartz epoxy flooring offers a compelling combination of practical benefits that make it a wise investment for any property owner:

- Quartz flooring solutions are renowned for their exceptional toughness. The incorporation of quartz aggregate creates a surface that can withstand heavy traffic, impacts, and abrasions, making it ideal for high-traffic areas like garages, commercial kitchens, and walkways.

- Time is money, especially in commercial settings. Quartz resin floors cure quickly, allowing you to resume using your space with minimal downtime after installation. This minimizes disruption to your daily operations.

- Quartz flooring is not limited to indoor spaces. Also, quartz-infused epoxy systems weather-resistant properties make it suitable for both interior and exterior applications. This allows for seamless transitions between indoor and outdoor areas, creating a cohesive design aesthetic.

- Safety is paramount, especially in areas prone to moisture or spills. The textured surface of quartz aggregate flooring provides superior slip resistance, minimizing the risk of accidents and promoting a safe environment.

- Who says functionality can’t be beautiful? We offer a variety of color options for the pigmented basecoat, allowing you to customize your quartz floor design to match your unique style. From classic and subtle tones to vibrant and eye-catching colors, the choice is yours.

The Wide Range Of Applications for Quartz Flooring Systems:

The versatility and practicality of quartz flooring systems make them suitable for a wide range of applications. Here are some examples:

- Transform your parking lot or garage into a durable and aesthetically pleasing space with quartz epoxy flooring. It can withstand heavy traffic from vehicles, resist oil spills, and provide excellent traction for safe navigation.

- High-traffic areas with frequent turns and stops require a flooring solution that can handle the pressure. Our seamless quartz flooring options offers superior durability and slip resistance, making it ideal for ramps, loading docks, and other high-torque areas.

- Extend your living space outdoors with a beautiful and weather-resistant quartz floor. The UV resistance and seamless finish create a visually appealing and easy-to-maintain outdoor area.

- Create a stylish and safe pool deck with durable quartz coatings flooring. The slip resistance, durability, and chemical resistance of this system make it perfect for poolside areas.

- Maintain a clean and hygienic environment in your commercial kitchen or restroom with quartz epoxy flooring. The seamless surface is easy to clean and disinfect, while the high durability withstands harsh chemicals and heavy foot traffic.

- Quartz flooring is a perfect solution for locker rooms, offering a durable, slip-resistant, and easy-to-maintain surface that can handle high moisture and frequent cleaning.

We Take The Art Of Quartz Flooring Systems Beyond Just Functionality

At Maui Epoxy Solutions, we take the concept of quartz flooring systems beyond just functionality. We believe it’s an art form that allows you to create stunning and unique surfaces for your space. Here’s how we can help you achieve your design vision:

- Elegant Quartz Floor Surfaces: Quartz flooring offers a luxurious and sophisticated aesthetic that elevates the look of any space. The seamless finish and natural beauty of the quartz aggregate create a visually appealing surface that complements various design styles.

- Residential Quartz Flooring: Bring the elegance and durability of quartz flooring into your home. It’s perfect for kitchens, bathrooms, basements, and even living areas, creating a beautiful and easy-to-maintain living space.

- Commercial Quartz Flooring Services: From high-end retail stores to industrial facilities, our commercial quartz flooring services cater to a wide range of needs. We offer expert installation and a variety of design options to create a floor that reflects your brand identity and enhances functionality.

- Custom Quartz Floor Designs: Don’t settle for cookie-cutter solutions. We work closely with you to understand your vision and create a custom quartz floor design that is tailored to your specific needs and preferences. This may involve incorporating specific color combinations, patterns, or logos into your floor.

- Polished Quartz Floors: For a truly dazzling effect, consider opting for polished quartz floors. The polishing process enhances the natural shine of the quartz aggregate, creating a reflective and visually expansive surface that adds a touch of luxury to your space.

- Low-Maintenance Quartz Coatings: Enjoy the beauty of your quartz floor without the hassle of constant upkeep. The smooth and seamless surface is easy to clean and requires minimal maintenance, saving you time and effort.

The Maui Epoxy Solutions Mark The Difference In Quartz Floor Installation

When it comes to quartz floor installation and quartz aggregate flooring, we go the extra mile to ensure your complete satisfaction. What sets us apart is, our team of highly skilled and experienced professionals are experts in quartz flooring systems. They take pride in meticulous craftsmanship and exceptional attention to detail.

Plus, We use only the highest quality quartz aggregates and epoxy materials from reputable brands. This ensures the long-lasting durability, performance, and aesthetic appeal of your quartz floor. From the initial consultation to the final walkthrough, we prioritize exceptional customer service. We are dedicated to understanding your needs, addressing your concerns, and exceeding your expectations.

Ready to Experience the Beauty and Strength of Quartz Flooring?

Contact Maui Epoxy Solutions today! We offer free consultations and estimates to help you determine the perfect quartz flooring system for your needs. Let us transform your space with a floor that is not only beautiful but also incredibly durable and functional!